Especially in production halls, warehouses, car dealerships and the like, heat builds up in summer – to the suffering of the workers.

In large halls, cooling systems such as conventional air conditioning systems quickly reach their limits. Especially if they are not always closed: If the hall door is opened briefly during a delivery, for example, warm air immediately flows into the cooled hall and the cooling system has to step on the gas again. This causes the energy costs to skyrocket …

How nice it would be if there was a cooling system,

…which cools your production hall quickly and cost-efficiently?

…where all employees feel comfortable (without annoying drafts or dust turbulence)?

…which you can also use for sensitive products such as medicines, foodstuffs and the like?

That sounds like wishful thinking? With surface cooling as hall cooling this is possible!

In this post, I’d like to explain exactly how hall cooling works using surface temperature control and how you can integrate it into your production hall or warehouse.

Difference in function of hall cooling by means of surface temperature control vs. classic air conditioning system

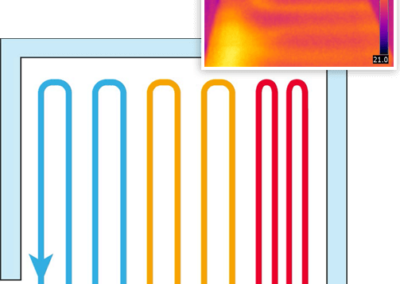

By surface temperature control is meant that not the air (as with a conventional air conditioning system), but the surrounding surfaces in the hall (ceiling, floor, wall) are cooled. This “surface cooling” works in principle like underfloor heating: only instead of warm, cool water is pumped through the pipes in the floor (and/or ceiling and/or wall). This cools the surface.

This cooling is sufficient to cool a large production hall with hot machines and many employees. To help you understand how this works, let me first explain 3 ways of heat transfer.

The 3 ways of heat transfer:

- Heat flow (=also called convection): In heat flow, heat is transferred via the air. It’s similar to using a hairdryer in the bathroom or the classic radiator. If you stand close to the radiator, it will be warmer than if you stand further away.

- Heat conduction: In this process, a specific body (e.g. the hotplate) is heated. If you put a pot on it, it will also get hot.

- Thermal radiation: Heat is transmitted by means of electromagnetic waves (infrared radiation). You can test the principle of heat radiation, for example, in winter at the ski hut: although you are sitting outside at 2,500 meters at minus five degrees in a T-shirt, you are not cold as long as the sun shines on your skin.

You can also use this principle of heat radiation for cooling systems. The “excess heat” always goes to the “cool surface”.

How are the surfaces in the halls cooled?

Apipe system ( as with underfloor heating) is installed inthe hall surfaces (wall, floor, ceiling ). Cold water (approx. 16 °C to 20 °C) flows through this, cooling the surfaces. (The exact temperature setting depends on the cold sensation of the respective worker).

Bodies that are warmer than the surfaces in the hall (machines, people, objects, etc.) transfer their heat to the cold surface via thermal radiation.

A pleasant radiation exchange is created: the body temperature of those working slowly adjusts to the room. The advantage: you feel a pleasant cooling (unlike the air conditioner, which blows cold at them selectively)

In a video we explain exactly how, for example, floor cooling works:

How can you integrate surface cooling in a hall?

- As floor cooling: If you decide on floor cooling, the pipe system is installed in the hall floor. This also works when heavy machinery is on the floor.

As wall cooling

: Here, the pipes are integrated into the hall walls.

As ceiling cooling

In the case of ceiling cooling, the system is installed in the ceiling. One advantage of this is that there is no equipment or machinery on the ceiling, and the entire ceiling area can be equipped with pipes. (The ceiling pipes can even remain uncovered under certain conditions).

6 reasons why your business will benefit from an indoor cooling system

In a separate blog post, we detailed the benefits of surface cooling. I’ll summarize them for you here:

#1 Reduce energy costs

One of the top reasons of any company for indoor cooling by means of surface cooling is the usually low energy costs.

- Less energy needed for cooling: With surface cooling, most of the energy is in the surfaces and not in the air. This means that during short-term ventilation (e.g. the hall door is opened) the energy loss to the outside is very low. If very warm air flows into the hall over a long period of time, the surface also gives off energy to the air, which then disappears again to the outside.

- Use natural cold from the ground: As an alternative, you can resort to the “almost free cooling” from the earth. Even in midsummer, the soil under the ground is about 15 degrees Celsius. Instead of cooling the pipe water with, for example, a heat pump, the water can be cooled by simply flowing through the cool earth. After the pipe system is installed in your hall, another pipe system is installed below the hall or in an area in the ground next to or outside the hall. This so-called “cold generation surface” is then connected to the hall piping system. The water is cooled under (or outside) the hall to the ambient temperature. This then flows into the warm production hall or warehouse. The warm water then flows back into the ground and is “naturally cooled” again. A cooling circuit that costs you practically nothing.

#2 Healthy climate for employees & the environment

Thanks to the radiation exchange, man and machine can radiate their excess heat to the cool surfaces. Air circulation is thus reduced to a minimum, the air is less dry and dusty. In addition, they are not constantly “cold blown” at work.

#3 No mold

Regardless of the humidity of the air can not form mold. Thanks to the surface cooling, the surfaces always have about 19 to 21 degrees. No condensation can form and therefore no mold.

A company from Innsbruck – Glas Peter – also had to deal with mold infestation – thanks to surface cooling, this is a thing of the past. (You can read more about it in this article /peter-schennach-sagt-begeistert-endlich-schimmelfrei/)

#4 Thanks to invisible shoring, no restrictions for machines & Co.

The pipes are installed practically invisible in the ceiling, floor or wall. Regardless of whether heavy machines are on the floor or shelves are on the wall – thanks to the low structure height, trucks, for example, can also drive into a hall unhindered. For halls, there is also an option to install the registers visibly (so you can save additional costs, if the appearance is not so important to you)

#4 Cools halls that are difficult to cool

Imagine your production hall has no walls – but is made entirely of glass. A horror scenario in high summer – but no problem for surface cooling. Even in apparently “non-coolable” halls, surface cooling can create a pleasant indoor climate. You don’t believe that? Then you should read the experience report of Fenster Breisau GmbH: How pleasant climate is created in a hall.

#6 Can also be used as hall heating in winter

With a surface cooling system, you can also heat the hall in winter. In principle, this works in the same way as cooling – except that instead of cool warm water flows through the pipes.

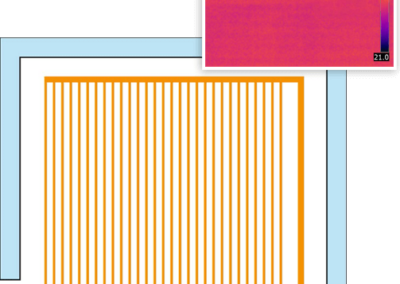

Hall cooling with the egger system: faster & more efficient cooling thanks to parallel system

We have been installing hall cooling systems with our egger system for more than 20 years. We have already integrated the system in production halls, car dealerships, aircraft hangars – but also in restaurants, schools and private homes.

You can cool virtually any room – old or new construction. The difference to “conventional” surface cooling systems? In the egger system, the pipes are laid in parallel (and not serially). Thanks to this so-called Tichelmann system, the cool water can flow through the pipes faster and more efficiently. Thanks to a tube spacing of 8 cm, the surfaces are also cooled more evenly.

The advantage: You minimize the lead time, the halls are cooled faster and with lower energy consumption – which saves energy costs. And every employee feels completely at ease.

You want to know more about hall cooling with the egger system?

Feel free to contact us by phone(+43 5223 411 68 11), by e-mail or via our contact form. We advise you during a free initial consultation and take a close look at your company and find a solution together.

Love greetings

Annette & Christian Egger