Conventional underfloor heating systems have long been established and are already standard for many building owners.

When obtaining offers, however, mostly underfloor heating is compared with underfloor heating and thus one mistakenly compares

Apples with oranges.

However, a more detailed selection is enormously worthwhile here!

Decisive for the comfort and economy of underfloor heating is:

- the laying distance of the pipes to each other as well as

- the type of flow (serial or parallel)

The distance between the pipes determines the flow temperature at which the heating system must or can be operated.

In general, the smaller the laying distance, the less flow temperature is required:

- more energy saving is possible

- more uniform and healthy is the surface temperature

- more independent in the choice of energy generation

As far as the type of flow is concerned, only the conventional types of laying (meander or screw principle) with serial flow (one after the other) are known so far.

This is an endless pipe which, however, is limited to a maximum pipe length of approx. 100 linear meters (depending on the manufacturer) per heating circuit for hydraulic reasons (pipe resistance). This hydraulic pipe length limitation also restricts the m² number of the respective heating circuit depending on the pipe spacing (see table).

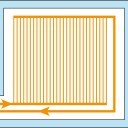

Parallel principle (Tichelmann)

Parallel principle (Tichelmann)

With the Tichelmann method of installation with parallel flow, completely different hydraulic laws apply with enormous advantages.

The pipe resistance is much lower here, which means that even with very narrow pipe spacing, considerably more m² can be laid per heating circuit (see table).

The following table shows in the first two lines that with the same pipe spacing there is an enormous difference in the possible maximum heating surface per heating circuit, depending on the type of flow (serial or parallel).

In the following lines you can see very well that if you want to use only one heating circuit for a certain standard room size, this is only possible with serial flow if the laying distance of the pipe is larger.

With parallel flow, the laying distance of the pipe always remains constant at the optimal 8 cm.

| Laying distance The tubes |

Running meter pipe per m² |

max. Area per heating circuit |

Type of flow The tubes |

|---|---|---|---|

| 8 cm | 13,5 m | up to 60 m² | parallel (according to Tichelmann) |

| 8 cm | 13,5 m | 7,5 m² | serial (one after the other) |

| 10 cm | 10 m | 10 m² | serial (one after the other) |

| 15 cm | 7,5 m | 13 m² | serial (one after the other) |

| 20 cm | 5 m | 20 m² | serial (one after the other) |

Further advantages of the parallel flow system

Another significant advantage of this system is that the spread (difference between supply and return temperature), is only a fraction of that of the traditional serial flow.

This results in:

- uniform surface temperature and

- lower supply temperature for the same average surface temperature.

With the parallel flow of the egger register, the optimal surface temperature control can be implemented, and thus the way is also clear for the optimal room temperature control.

“Healthy tempering instead of heating/cooling”.